신우개발주식회사

- COMPANY

- BUSINESS

- PERFORMANCE

-

SAFETY

- Safety Policy

- Safety Goal

- Organization Chart

- Major safety management services

- Safety inspection based on self-audit program

- Implementation of safety supervision for tower crane and lift for construction

- Nondestructive test of equipment

- Inspection of construction equipment before bringing in

- Safety Training

- Production and distribution of safety book

- Q&A

- EQUIPMENT

- PR CENTER

Safety Management

- Safety Policy

- Safety Goal

- Organization Chart

- Major safety management services

- Safety inspection based on self-audit program

- Implementation of safety supervision for tower crane and lift for construction

- Nondestructive test of equipment

- Inspection of construction equipment before bringing in

- Safety Training

- Production and distribution of safety book

- Q&A

-

- Major safety management services

- Safety inspection based on self-audit program

- Implementation of safety supervision for tower crane and lift for construction

- Nondestructive test of equipment

- Inspection of construction equipment before bringing in

- Safety Training

- Production and distribution of safety book

- Q&A

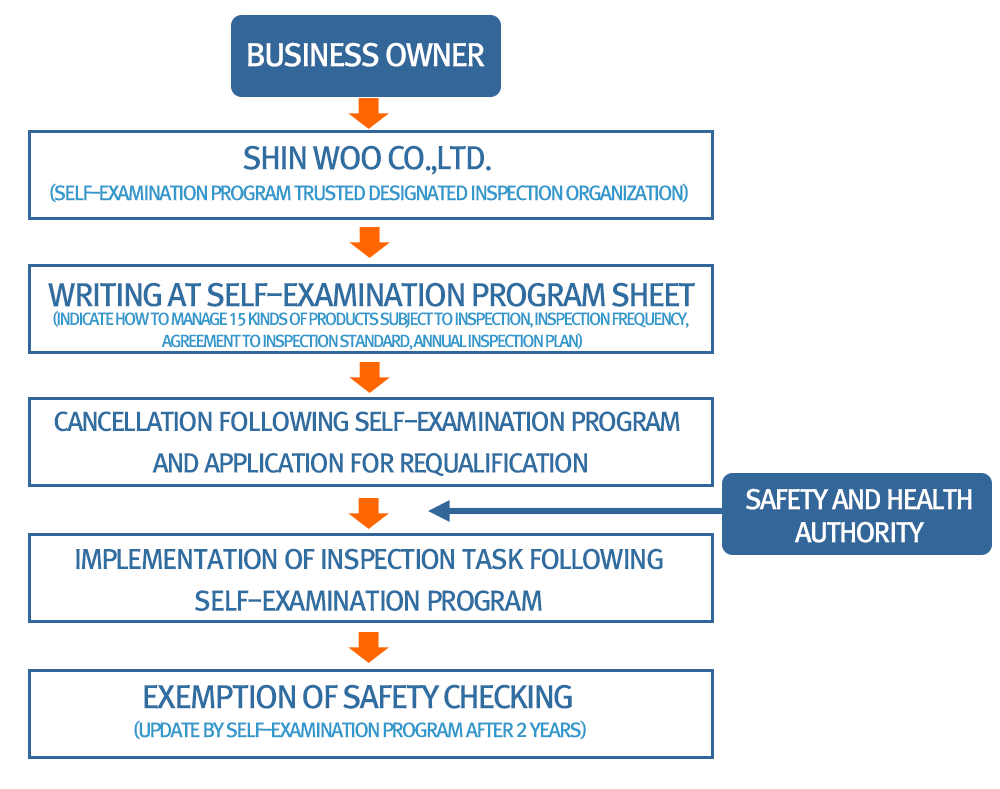

Safety check following the self-examination program

-

Safety check following the self-examination program

-

Safety inspection system

Following the article 98 of Industrial safety and health act, employer who use harmful or hazardous machinery should get inspection of their machinery to know if their safety related performance meets the inspection standard. Harmful or hazardous machinery that did not go through the inspection or machinery that failed to pass the inspection cannot be used in Korea. This system is designed to control safety performance of the harmful or hazardous machinery and prevent industrial disaster.

-

Relevant regulation

- Article 39 of Industrial safety and health act (Safety inspection)

- Article 98 of Industrial safety and health act (Safety inspection following the self-examination program)

(Trust inspection by autonomous safety inspection organization designated by Minister of Employment and Labor :

clause 4 of article 98 at Industrial safety and health act)

- Enforcement ordinance article 78-1 at Industrial safety and health act (Machinery subject to safety inspection, etc.)

- Enforcement ordinance article 125~126 at Industrial safety and health act (Exemption of safety inspection, etc.)

- Announcement 202-42 from Ministry of Labor (Announcement on safety inspection procedure)

-

Worksite subject to inspection

- All the worksites that possess harmful or hazardous machinery/equipment where Industrial safety and health act is applied

- Central government, Local government, Government-invested institute, etc.

-

Safety inspection system

-

Specification and coverage scope by type of machinery, etc. subject to inspection

No Machine. Device Specification and coverage scope by type 1 Press - Press or Shearer driven by power with pressuring capacity over 3 ton

However, machine belonging to one of the items below is excluded - A. Hot forging press, Forging hammer, Compression press for bonding wood,etc., Tomson Press, Sealing machine, Powder compaction molder, Extruder & Bender, Pressure molder for rubber and sand, etc., Automatic turret punch press, Ironworker for multi-purpose, Die spotting press, Orthodontic press

- B. Press or Shearer with less than 6 mm stroke into which part of human body cannot be dragged to the limit of danger

- C. Revolving shearer with round type rotating blade, Nibbler, Coil slitter, Shearer and Notching machine for section steel and bar steel

2 Shearer 3 Crane - Crane that operates by power over 2 tons of safe working load is applied. However, items below are excluded

- A. Construction machine subject to ‘Construction machinery management act’

- B. Vehicle (Crane for recycling) of which the pincers is directly attached to boom using the hanging device as the pincers not relying on the wire rope for hoisting/releasing

- C. Vehicle manufactured for towing or rescuing of other vehicles

4 Lift - Lift with loading capacity of over 0.5 ton (over 0.1 ton in case of lift for carrying goods to be moved) is impacted. However, lift for automobile maintenance, industrial lift for moving less than 3 meters, part of dedicated automation facility people are not expected to access are excluded.

5 Pressure vessel - A. Fluid handling vessel for chemical or other process (vessel for air or nitrogen) which exceeds 2kgf/㎠ by gauged design pressure. However, one of the items below are excluded.

- 1) Vessel with less than 150 mm of inside diameter, width, height or section diagonal (in case pipe is used, less than 150A of nominal diameter) regardless of vessel’s length or pressure

- 2) Nuclear vessel

- 3) Water cooling ductal type condenser (However, limited to the case cooling water flows at the body and working pressure at the pipe is lower than that at the body)

- 4) Vessel that handles water with less than working temperature of 60 degree centigrade only (However, in case flashing point of aqueous solution under atmospheric pressure is over 85 degree centigrade, minimal additive may be included at water)

- 5) Plate type heat exchanger

- 6) Fin type air cooler

- 7) Accumulator

- 8) Hydraulic, water pressure, air pressure cylinder and oil infuser/ejector

- 9) Pressure vessel that can drag a human

- 10) Tank lorry for vehicle

- 11) Piping components used for purpose of plumbing, flux measurement or control

- 12) Silencer or strainer (including filter) which is subject to one of the items below.

- A. There is no welding joint except for attaching flange.

- B. External diameter of body is smaller than 320 mm and nominal diameter at piping connection is larger than 1/2 of External diameter of body.

- 13) Part of machine/device is component of the part pressured such as body or withstanding plate

- 14) Multiplication result between working pressure (unit : MPa) and internal capacity of vessel (unit : m3) is less than 0.1 and subject to one of below.

- A. Component of machine/device

- B. Equipment attached to pressuring device such as pump or compressor of which the purpose is heat exchange (However, limited to the case the handled fluid is not the fluid in the relevant process or a hazardous material listed at schedule 1 of Safety and health rule)

- 15) Vessel for containing products and carrying to sell or supply

- 16) Direct fired tube type heater for processing

- 17) Closed type expansion tank used for other than industry

- 18) Component of machine/device subject to safety inspection

- 19) Component of small sized air compressor (At the upper part of pressure vessel, reciprocating compressing device is fixed/attached)

- 20) Pressure vessel with less than 2kgf/㎠ of working pressure

- B. Scope of vessel inspection

- 1) In case connected to exterior pipe by welded connection, up to welded joint in the circumference direction

- 2) In case connected to exterior pipe by screw connection, up to first screw joint

- 3) In case connected to exterior pipe by flange connection, up to first flange

- 4) In case attachment is directly welded to internal pressure part, up to the welded joint

- 5) Including cover plate, welding joint, bolt/nut and gasket that receive pressure from manhole or hand hole

- ※Fluid handling vessel for chemical processing is the facility used for storing, separating, transferring and mixing the fluid used for chemical processing such as vaporization, absorption, distillation, drying and adhesion. Reactor, mixture tank, heat exchangers (heater, cooler, vaporizer and condenser, etc.) filtering devices and storing vessels are some of them. And the vessel that handles hazardous material indicated at schedule 1 of Industrial safety and health standard is also included.

6 Gondola - Only gondola that operates by power is impacted. However, gondola installed at crane, gondola using engine as power, gondola installed at the angle lower than 45 degrees from ground are excluded.

7 Local ventilation equipment - Applied to local ventilation equipment installed for prevention of following hazardous materials (49 kinds) only

-

1. Dianisidin and its salt

2. Dichlorobenzidine and its salt

3. Beryllium

4. Benzotrichloride

5. Arsenic and its inorganic compound

6. Asbestos

7. Alpha-naphthylamine and its salt

8. Vinyl Chloride

9. Ortho-tolidine and its salt

10. Chrome mineral

11. Chromic acid zinc

12. Nickel sulfide

13. Volatile coal tar pitch

14. Bromopropionate

15. Hexavalent chromium compound

16. Lead and its inorganic compound

17. Normal-hexane

18. Nickel (Insoluble inorganic compound)

19. Dimethyl Formamide

20. Benzene

21. Carbon bisulfide

22. Cadmium and its compound

23. Toluene-2, 4-Diisocyanate

24. Trichloroethylene

25. Formaldehyde

26. Methylchloroform (1,1,1-Trichloroethane)

27. Grain particles

28. Manganese

29. Methyldiphenyldiisocyanate (MDI)

30. Phthalic anhydride

31. Methyl Bromide

32. Mercury

33. Styrene

34. Cyclohexanone

35. Aniline

36. Acetonitrile

37. Zinc Oxide

38. Acrylonitrile

39. Acrylamide

40. Aluminum

41. Dichloromethane (Methylene chloride)

42. Welding hume

43. Glass silicic acid

44. Cobalt

45. Chrome 4

46. Talc

47. Toluene

48. Aluminum sulfate

49. Hydrogen sulfide

However, if result of work environment measurement value by exposure standard for recent 2 years is less than 50%, then excluded.

8 Centrifuge - Industrial centrifuge operated by power for the purpose of separation between fluid and solid or of separating at least 2 kinds from the materials is affected. However, centrifuge subject to following items is excluded.

- A. Revolving movement energy of the rotor is less than 750J

- B. Centrifuge of which the top speed of circumference exceeds 300m/s

- C. Centrifuge used only for nuclear energy product process

- D. Centrifuge used for continuous process at automatic operating facility

- E. Centrifuge subject to chemical facility

9 Roller - Roller operated by power and its pressure bringing out plastic deformation of rubber, rubber compound or synthetic resins or softening of them is affected.

- However, closed structure roller that cannot be accessed by worker is excluded.

10 Injection molding machine - Injection molding machine operated by power for forming plastic or rubber is impacted. However, those subject to one of below is excluded.

- A. Injection molding machine that activates clamping device

- B. Interactive Injection molding machine

- C. Compress/Transfer type Injection molding machine

- D. Injection molding machine for manufacturing boots

- E. Injection molding machine with less than 294KN of type completing power

- F. Blow Molding machine

11 High place worktable - Limited to the High place worktable attached to the vehicle (When the worktable is loaded at the working space of freight/special car indicated at article 3 of ‘Automobile management act’) driven by power that can move the worktable with the worker on it. However, worktable subject to items below is excluded.

- A. Tail lift

- B. Boarding ramp lower than 2m in boarding height

- C. Equipment to support airplane on the ground

- D. Firefighting equipment based on Framework act on fire services

- E. High place work vehicle for farming (Limited to inspected product subject to Agricultural mechanization promotion act)

12 Conveyor - Conveyor system that includes conveyor of belt, chain, roller, trolley, bucket, screw which can convey raw materials, half-finished goods, freight, etc. by power. However, conveyor or section subject to following cases are excluded.

- A. In case sum of rated output at driving part motor is less than 1.2kw

- B. In case total moving distance of conveyor with belt,chain,roller,trolley,bucket,screw is less than 10m. In this case, section subject to 마~파 is not included at moving distance.

- C. Conveyor to carry human being like moving walk

- D. Equipment to support airplane on the ground (Movable conveyor that loads freight to airplane)

- E. Conveyor or section for carrying things used by general public such as food tray in restaurant

- F. Conveyor or section used at section or section itself subject to Harbor act, Mine safety act and Airport facility act

- G. Section not for conveyor with belt,chain,roller,trolley,bucket,screw inside conveyor system

- H. Closed type conveyor or section which human cannot access during operation. In this case, conveyor system of which the upper,lower,side part is surrounded by partition except for the feeding entrance and outlet is included. And in case inspecting door exists at partition, conveyor that cannot be accessed during operation by measures below is included.

- 1) In case conveyor system stops when inspection door is opened

- 2) In case internal wire mesh, responsive protection device, etc. functions when inspection door is opened.

- I. Conveyor or section installed inside cell of industrial robot which human cannot access. In this case, limited to the industrial robot cell protected by barricade, responsive protective device, etc.

- J. Conveyor or section with max speed less than 150mm/s that has no risk of harming human since dangerous part like driving part is not exposed.

- K. It is used in a place where people are prohibited from entering for the quality of production, such as the painting process, and there is no risk of human access by installing a sensitive protective device or section.

- L. Movable conveyor (Mobile equipment) system or section that can convey by itself by power with structure of stacker of similar type.

- M. Individual self-propelled overhead conveyor system or section

- ※ Unit section for inspection is classified into control section unit (control panel installation unit) inside conveyor system. However, if necessary, it can be classified by the process section units.

13 Industrial Robot - Applied to industrial robot cell that includes multi-joint robot with more than 3 rotary joints. However, case subject to items below is excluded

- A. Industrial robot cell composed of robots with lower than 250mm/s max speed at TCP

- B. Industrial robot cell composed of robots with rated output of each driving part’s motor less than 80W

- C. Industrial robot cell composed of robots with max motion zone (Standard : Tool mounting surface or Installed flange wrist plates) less than 0.5m from robot’s pivot

- D. Cell installed inside the facility and human access is impossible. In this case, limited to when facility is closed and thus contact with robot is not possible, and if installed inspection door with interlocking device is opened, operation is stopped.

- E. Cell of which the upper,lower,side face is all surrounded by partitions except for the feeding entrance and outlet for raw materials, etc. In this case, limited to when responsive protection device is installed at feeding entrance and outlet and conveyor stops if inspection door is opened if ever it exists at partition.

- F. Cell installed at the place where human access is prohibited during normal operation for quality of production such as painting process. In this case, limited to when interlocking device and locking device is installed at entrance and responsive protection device is installed at opening except for entrance and thus there is no concern for human access.

- G. Cell that stops if entrance at 1.8m high barricade installed all around the robot is opened. In this case, limited to when there is no opening except for entrance and entrance interlocking device does not restart though door is closed and it restarts by separate starting device.

- H. Cell adjacent to between cells connected sequentially. Responsive protection device, etc. is installed between the cells and barricade higher than 1.8m is installed at the side except for between the cells. And robot stops when entrance is opened. In this case, limited to when there is no opening at the section where barricade is installed except for the entrance.

- Press or Shearer driven by power with pressuring capacity over 3 ton

-

Safety checking process following the self-examination program

-

Effect of safety checking trust following self-examination

-

Effect of safety checking trust following self-examination

- Securing safety for inspection facility

(Prevent incidental failure accident by reducing frequency of inspection cycle for facility)

- Tracking management for securing safety of inspection facility is easy

(Secure safety of facility by history management such as regular replacement of expendable parts of facility)

- Resolve anxiety factor over the inspection by reducing failure factor that may be encountered during safety inspection

- Enhance operation rate of facility by prompt response when urgent or abnormal situation occurs

- Providing advice and convenience regarding safety inspection for worksite person involved at safety management task

- Effect of easing the burden for worksite about the management of inspection facility

(Establishment of systematic management system like identifying problems after inspection, solution suggestion and maintenance)

-

Effect of safety checking trust following self-examination

-

Client inquiry

Email msw0321@naver.comTel safty Team031-8087-7223

-

Civil affairs processing

-

Procedures of civil affairs processing

- Application (Phone, Fax, Post mail, Visit, Internet)

- Receiving

- Processing at the division in charge

- Reply result

-

Procedures of civil affairs processing